Conveyor Belt Troubleshooting

Common Causes of Belt Failure:

1. Seized or Worn Rollers/Idlers

2. Pulley and Drive Failures

3. Belt Contamination - Oils, Chemicals, or other foreign materials.

4. Inadequate Belt Tension - Slippage, stretching, mistracking.

Daily Conveyor Belt System Maintenance Checklist

[ ] Inspect belt tracking and realign if drifting due to aggregate buildup.

[ ] Check belt tension; adjust to prevent slippage on incline under load.

[ ] Examine belt surface for wear, cuts, or gouging from sharp aggregate.

[ ] Clean dust and debris from pulleys, idlers, and return rollers.

[ ] Inspect drive pulley lagging for wear or contamination.

[ ] Check idlers and rollers for free rotation; replace if seized or noisy.

[ ] Ensure belt cleaners/scrapers are in contact and not worn out.

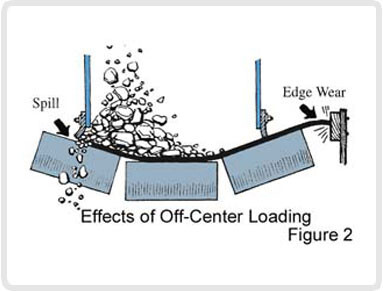

[ ] Verify that chute and loading points are centered and not overloading one side.

[ ] Inspect structure for material spillage and clear as needed.

[ ] Lubricate bearings and moving parts per OEM guidelines (use high-temp grease if required).

[ ] Check motor temperature and listen for abnormal noises.

[ ] Ensure all guards, covers, and emergency stop mechanisms are intact and functional.

[ ] Document findings and any corrective actions taken.

Tracking/Training Belt Procedures

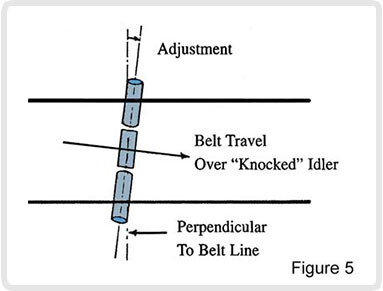

Training or tracking the belt on your radial stacker or conveyor system is a process of adjusting idlers, pulleys and loading conditions in a manner which will correct any tendency of the belt to run other than centrally. The basic rule which must be kept in mind when tracking a conveyor belt is simple, "THE BELT MOVES TOWARD THAT END OF THE ROLL/IDLER IT CONTACTS FIRST."

Conveyor Belt Tracking Guide

1. Understand Belt Tracking Basics

-

-

- Tracking means aligning the belt to run straight on the conveyor.

- Most belts naturally want to move toward the tighter side of the system.

-

2. Common Causes of Belt Misalignment

-

-

- Uneven or improper tension

- Worn or misaligned rollers/pulleys

- Build-up of material on rollers or belt

- Poor belt splicing

- Uneven load distribution

-

3. Step-by-Step Belt Tracking Procedure

Step 1: Inspect the System

-

-

- Check for material buildup on pulleys or rollers.

- Inspect belt condition (no tears, frays, or stiff edges).

- Ensure all pulleys and rollers are square and level.

-

Step 2: Tension the Belt Properly

-

-

- Set even tension across both sides.

- Over-tensioning can cause stretching; under-tensioning can cause slippage and misalignment.

-

Step 3: Adjust the Tail Pulley First

-

-

- To move the belt left, tighten the right side of the tail pulley.

- To move the belt right, tighten the left side of the tail pulley.

- Make small adjustments (1/4 turn at a time).

-

Step 4: Observe and Adjust Drive Pulley (if needed)

-

-

- Typically used as a fine adjustment if tail pulley doesn't solve tracking.

- Same principle applies: the belt moves toward the tighter side.

-

Step 5: Use Return Rollers for Fine-Tuning

-

-

- Adjust return idlers (especially training idlers) to help guide the belt back to center.

- Self-aligning idlers can help automatically correct tracking.

-

5. Preventive Measures

-

-

- Keep the belt and pulleys clean.

- Schedule regular inspections.

- Use crowned pulleys or tracking guides (v-guides) if belt misalignment is persistent.

-

Common Mistakes to Avoid

-

-

- Making large adjustments too quickly.

- Adjusting too many points at once.

- Ignoring roller/pulley alignment.

- Failing to lock components back into place.

-